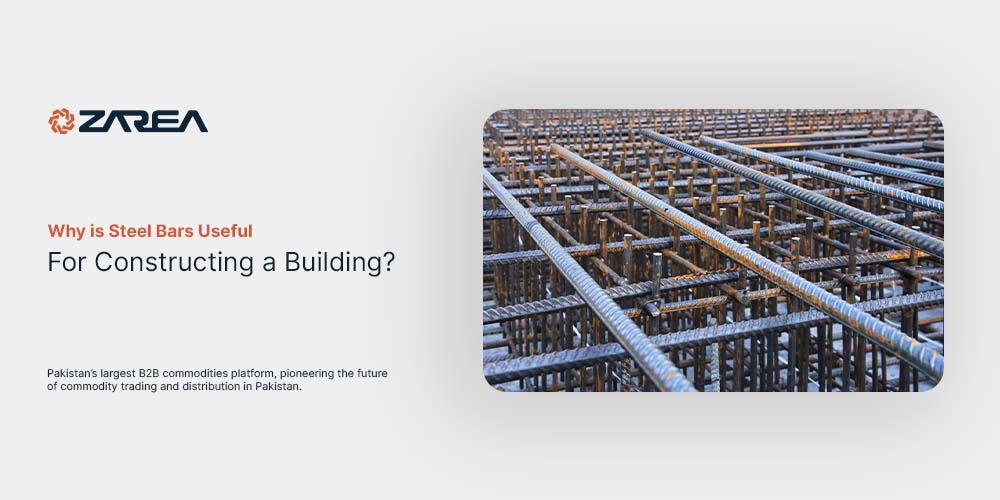

Introduction – Steel Bars:

Steel Bars empower the concrete structure and allow for specialized designs. It’s like cantilever constructions (elongated structures supported solely at one end). An additional advantage is that it enables the utilization of lighter concrete slabs. These slabs need reduced support and have quicker construction period. These emporing bars are commonly referred to as rebars which are typically known as steel bars.

What is Steel Bar?

Let’s begin with the fundamentals. “A steel bar is a solid cylindrical piece that can have various forms. Although their forms share many similarities with steel tubing, steel bars are solid and come with extra variations suitable for more specialized uses.”

Mughal Steel has several features that, when combined, offer maximum strength and durability to RCC structures. Why is Steel Bars Useful For Constructing a Building. The most well-known of these properties is its corrosion-resistance, ductility, which makes its earthquake-proof and higher tensile strength.

However, there is one more feature that adds an extra layer of robustness to the structure – the cross ribbed pattern on the outer surface of the Mughal Steel Bar!

For most laypersons, this pattern might seem fairly ordinary. But as any civil engineer would tell you – they are crucial for keeping the concrete and the steel bonded together.

What does the pattern on Mughal Steel do?

Earlier ordinary smooth Steel had higher instances of material slippage i.e., concrete often slipped, causing structural collapse. This was mostly due to low bonding between concrete and steel bars. Mughal steel with cross ribbed patterns was introduced to provide better bonding with concrete. The deformed patterns provide a better grip with construction materials.

This enhanced grip is crucial for keeping the structure intact during natural calamities such as earthquakes or floods when the stability of structures can reduce the loss of life and property.

What do you need to keep in mind while selecting Cross Ribbed Mughal Steel?

Pattern shape:

Every Mughal Steel bar comes with a particular pattern on its outer surface – called ribs and lugs or cross-ribbed pattern. The specific pattern comes in several variations and is decided according to how the Mugal Steel bar will be used and the properties that are most desired.

For example, decreasing the height of lugs makes the Mughal Steel more flexible, while transverse ribs binding in the longitudinal ribs lead to the highest bond, but lower bending capacity.

Pattern formation:

Consistency of the pattern and the technique of forming it is also an important factor you must pay attention to while selecting a cross ribbed Mughal Steel bar. The best pattern is made with CNC notch cutting machines, which ensure uniformity in the rib pattern giving the Mughal Steel bar higher fatigue strength. Below are the top Six companies in Steel Bars ranked according to our study

1- Mugal steel

2- Ittefaq Steel

3- Amreli Steel

4- FF Steel

5- Agha Steel

6- Kamran Steel

7- Hunza Steel

8- SJ Steel

The Bottom Line:

Mughal Steel is undoubtedly the BEST for any RCC construction, and there is absolutely no reason why you should even consider working with ordinary Steel. They are extra strong, earthquake resistant, corrosion-resistant, and, as compared to ordinary Steel, provide higher stability and strength to all types of buildings.

The only thing you need to ensure is that you buy your Mughal Steel from a reputable and well-known manufacturer. The latest and tested construction practices to get the best value for your investment.

Are they rolled hot or rolled cold?

Steel bars are available for purchase in both cold rolled and hot rolled varieties. Similar to other rolled products, hot rolled is generally more cost-effective and utilized for applications that do not require tight tolerances, whereas cold rolled offers greater precision but is also pricier.

If you have any feedback or questions, tell us in the comments section below! You can also start a discussion on Zarea Forum.

FAQ’s:

What are types of steel bars?

In the market, there are five distinct types of steel bars: hot rolled deformed bars, cold rolled deformed bars, mild steel bars, twisted steel bars, and welded steel bars.

What is the cost of 1 kg of steel?

Zarea provides the top Steel prices in Pakistan. The price of 1Kg steel currently is 236 per KG, amounting to 236,000 PMT to 250 per KG, totaling 250,000 PMT Rs.

What are the 4 different general categories of steel?

Steel is categorized and classified into four categories:

- Steels made from carbon.

- Alloyed steels.

- Inox steels.

- Instrument steels.