Introduction – Sugar Market in Pakistan:

The sugar market in Pakistan occupies a prominent status throughout the nation, boasting a production capacity of 5 million tons annually. Pakistan ranks as the fifth-largest sugarcane producer, the eighth-largest sugar consumer, and the sixth-largest cane sugar producer globally. The volume and excellence of sugar production in Pakistan is remarkable, and the industry is now embracing the incorporation of sustainable methods in the manufacturing and recycling of byproducts. Zarea Limited serves as a one-stop solution for sugar products and sugarcane bagasse so you can integrate sustainability into your business without any hassle.

Sugar Market of Pakistan – A Brief Overview:

The sugar industry is the second largest industry in Pakistan with over 89 sugar mills across the country producing a significant amount of cane sugar annually. Sugarcane is the raw material for cane sugar abundantly used in the making of raw and refined sugar. Typically grown along the areas with high delta covering area of over 1.2 million hectares providing raw material for over 90 sugar mills across Pakistan.

The sugar industry holds the position of being the country’s second largest agriculture-based industry employing over 1.5 million people. From the cultivation and processing of sugarcane in the MY23, approximately 100-150 million people were provided direct employment worldwide.

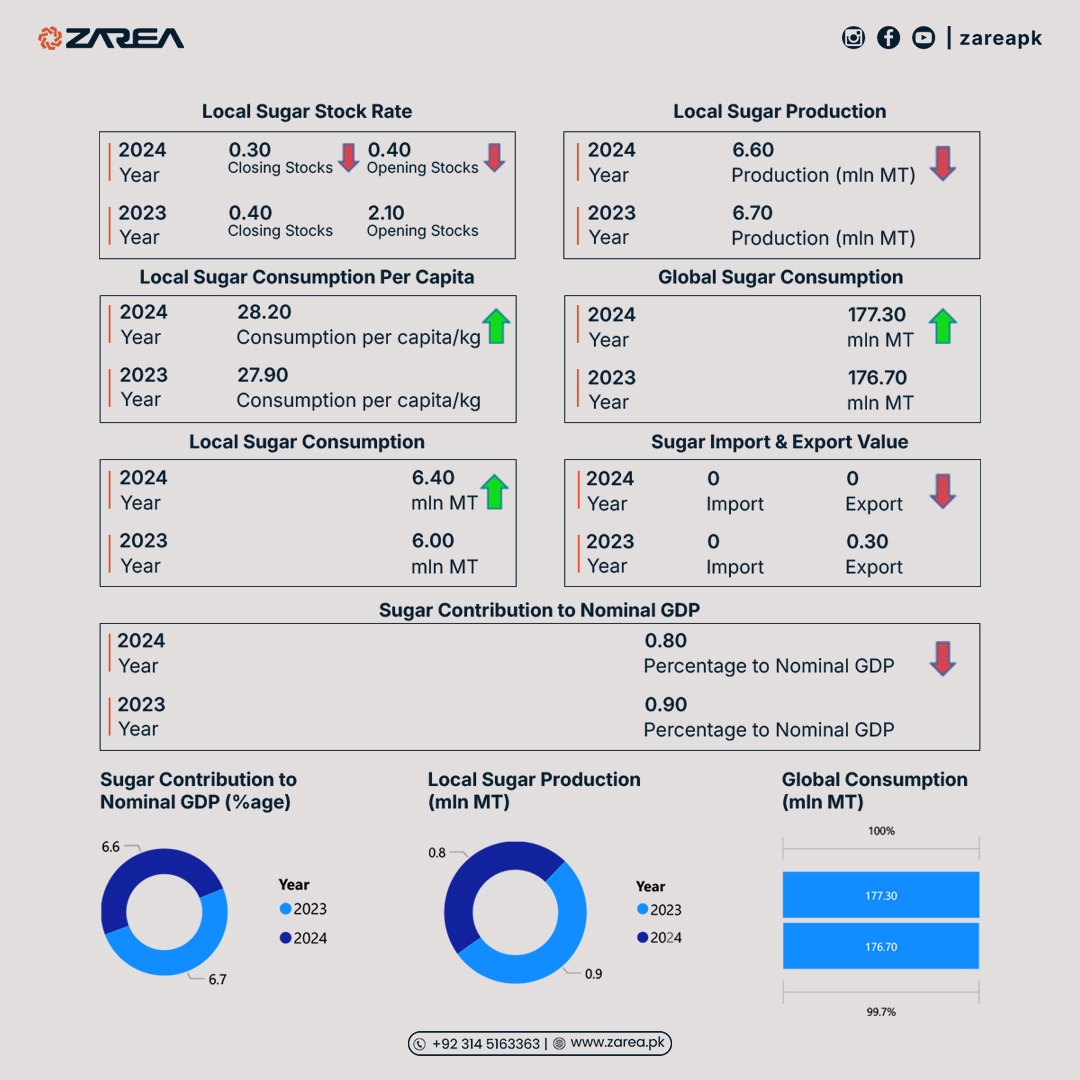

Being one of the most important agricultural and cash crops in Pakistan, sugarcane has contributed approximately 3.7% to the agriculture sector, with over 0.9% of Pakistan’s GDP during MY23. Pakistan produced over 6.7mln MT during MY23 and is expected to decline in MY24 by approximately 0.1%. The sugar consumption during the MY23 clocked in at over 6.0mln MT and is expected to increase by approximately 6.6% by MY24. Additionally, the plantation area is also expected to expand during MY25 by 5.6% year-on-year, reaching approximately 1.3mln hectares.

Phases of Sugar Production:

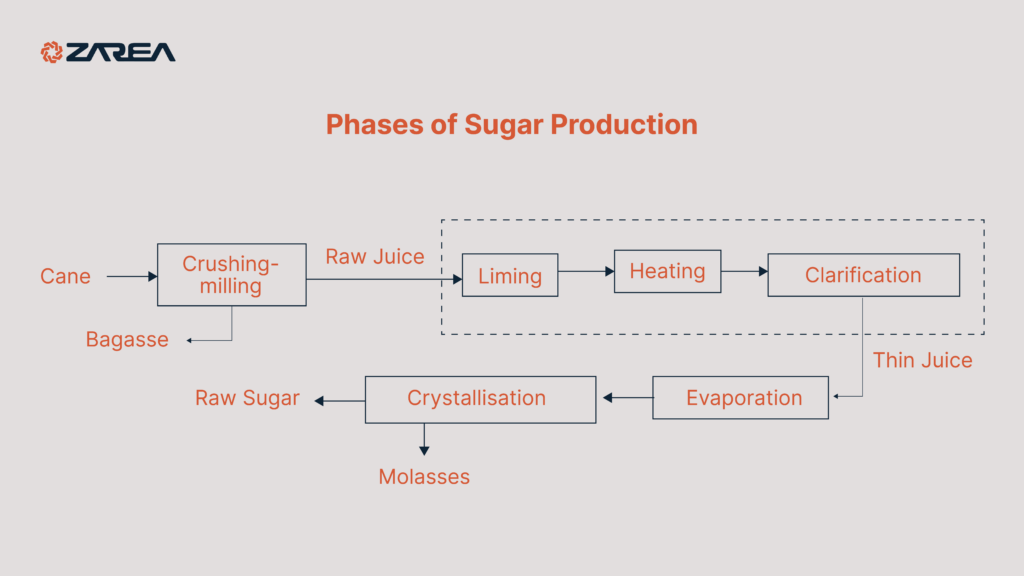

Sugar is a common sweetener used in various products all over the world. It is primarily extracted from sugarcane and sugar beet and serves as a crystalline food supplement widely used in food and various products. The production of sugar entails transforming sugarcane into both raw and refined sugar. First, sugarcanes are cleaned and transported to the crushing mill for juice extraction.

This juice is subsequently purified and clarified to eliminate any contaminants. The solution is subsequently evaporated and crystallized to isolate the liquid, after which it is centrifuged to extract the molasses from the crystals. In the end, these crystals are dried and packaged as brown sugar or are further refined to yield white sugar crystals. In addition to that, powdered or ultrafine crystallized sugar can also be produced from this process.

Sugarcane – A Versatile Raw Material:

Sugarcane is utilized not only for making sugar, but it also serves as a versatile source for numerous other products. The byproducts generated from the sugar-making process can also be reutilized in creating pharmaceuticals, ethanol, paper goods, organic fertilizers, and more.

Byproducts of Sugar Production

The following are the residues left after the sugar production process in Pakistan:

Sugarcane Bagasse: The byproduct of sugar production that is rich in nutrients is bagasse, a coarse fibrous substance remaining after the juice has been extracted from sugarcane. It is commonly utilized as a renewable energy source for onsite power generation and beyond.

Molasses: The dense and sticky liquid that remains after the sugarcane syrup undergoes clarification and crystallization. Molasses is a primary component of brown sugar and can also be utilized in several other applications.

Filter Cake: It is the leftover material after filtration and serves as a rich source of phosphorus and various organic substances, making it perfect for use as fertilizers and soil enhancement agents.

Integrating Sustainability into the Sugar Market:

The sugar sector has demonstrated its versatility as the leading industry, primarily utilizing steam and minimal electricity to operate the mills. Additionally, sugarcane bagasse acts as a perfect renewable energy resource since it can be burned to generate energy for the mills. 1 MT of sugarcane cut provides approximately 120Kg Sugar, 36Kg Filter Mud, 36Kg Filter Mud, 250 Kg Bagasse, 60Kg Straw, and 100Kg Tops.

Sugarcane bagasse is produced over 4.4 million MT in Pakistan which has the potential of generating 1000 MW of electricity. Therefore, it is one of the most ideal and abundantly produced residues with high potential to produce renewable energy. Proper utilization of the residue reduces the cost of sugar production in Pakistan. Bagasse serves as a valuable energy source for powering the boilers that heat the sugarcane juice. Furthermore, it can be utilized for producing Medium Density Fiber Board (MDFB) in certain sectors as an alternative to natural wood.

The sugar market in Pakistan is adopting sustainable methods to enhance energy efficiency through the use of High-Pressure Cogeneration (HPC) technology.

Unfortunately, only five out of 89 sugar mills in Pakistan have this technology so far. It is a method of power generation using high-pressure boilers to generate electricity by utilizing sugarcane bagasse. HPC technology consumes 46% less sugarcane bagasse to generate electricity as compared to the traditional low-pressure technology being used in the sugar mills of Pakistan. The abundance of bagasse production annually has the potential to generate over 830GWh per year.

Conclusion:

The sugar industry has the immense potential to play a significant role in Pakistan’s energy matrix. Various incentives are being offered to the power-generating sugar mills of Pakistan to revolutionize the economy and energy sector of Pakistan. Zarea Limited covers every ground to provide the people of Pakistan with affordable products from top-quality bagasse to premium sugar at your doorstep! Check out our website today to explore the categories of the commodities we are offering.

FAQ’s:

What is the price of a 50 kg sugar bag in Pakistan?

1 kg of sugar varies in price from PKR 120 to PKR 170, while a 50 kg bag is priced between PKR 7,400 and PKR 7,800 depending on the area.

What is the 1 kg sugar price?

The price of sugar is round about 148Rs per kg. It depends on the city or designated area.