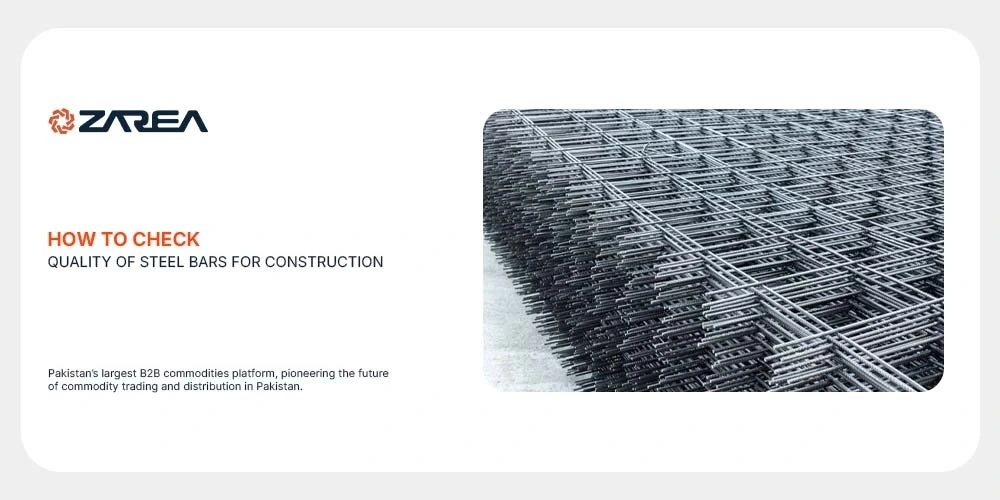

Introduction – How to Check Quality of Steel Bars?

As we all know steel bars support all buildings, bridges, and infrastructures. Because these structures serve as part of the fundamental framework of any concrete construction. Therefore, if you want to assess the quality of steel bars, then you can test the essential abilities of engineers, contractors, and quality control specialists. On the other hand if you are utilizing inferior or flawed steel, it can jeopardize a structure’s long-life, safety, and strength. So, if applied to inferior or flawed steel, it may result in expensive repairs, disaster, or structural failure.

In this blog post we will assess the quality of steel bars while examining and going over several ways to discuss safety measures. Meanwhile we are promoting laboratory testing and on-site inspections to also make sure your safety measures for steel bars. These tests and inspections not only assure your safety but also ensure your building project complies with all safety and regulatory requirements. This is all we can do!

To see product listings, place large orders, and get the best deals. Visit Zarea right now! It is Pakistan’s biggest business-to-business (B2B) commodities marketplace and is establishing the norm for the country’s future commodity trade and distribution.

Why Steel Bar Quality Matters:

The tensile strength that concrete by itself cannot supply is provided by steel reinforcement, or rebar. The following outcomes might occur if low-quality steel bars are used:

- Concrete breaking too soon

- Decreased structural soundness

- Lower capacity to support loads

- quicker degradation when exposed to the environment

- Costlier upkeep and repairs

- Possible risks to occupants’ safety

As a result, quality testing is essential to creating long-lasting, safe buildings and goes beyond simple legal requirements.

Key Parameters to Evaluate Steel Bar Quality:

The following factors must be considered in order to comprehend how to assess the quality of steel bars:

Chemical Composition

High-quality steel must have a balanced chemical makeup. Excessive carbon, sulfur, or phosphorus can make the steel brittle and prone to corrosion.

- Spectrometric Analysis: You have to assess the elemental composition through spectrometric analysis. It’s a chemical composition approach to testing steel bars (e.g., carbon, manganese, and sulfur).

- Laboratory Chemical Testing: These tests confirm compliance with industry standards like IS 1786 or ASTM for steel bars.

Mechanical Properties

These dictate how the steel responds to stress.

- Tensile strength: It is the highest weight that steel can support before failing.

- Yield Strength: The stress at which irreversible deformation starts.

- Elongation: Indicates a bar’s ductility, or how far it can stretch before breaking.

Physical Properties

Simple inspections guarantee that the steel bars adhere to the required surface requirements and dimensions.

- Dimensional Accuracy: Length and diameter must be within acceptable limits. It’s one of the physical properties parameters to evaluate steel bar quality.

- Surface Quality: To be free from rusts, cracks, pitting, and laminations to insure safety measures. This is because it is another physical property test for steel bars.

Detailed Instructions for Evaluating Steel Bar Quality:

Visual Inspection

Start with a straightforward but powerful visual evaluation:

- Check for uneven deformations, rust, or cracks.

- Verify the length and pattern of the ribs for consistency.

- Make sure there are no warps or bends.

Dimensional Verification

Use tools like:

- Vernier caliper to measure diameter

- Weighing scale to verify weight per meter

- Ensure the bars conform to standards like IS 1786.

Tensile Strength Test

Conducted using a Universal Testing Machine (UTM):

- A sample bar is stretched until it breaks.

- The stress vs. strain curve helps determine maximum load capacity.

Yield Strength Test

Performed alongside the tensile test:

- Identifies the stress point at which the bar starts to deform permanently.

Elongation Test

- In order to determines the maximum stretch that steel can withstand before breaking.

- You have to shows ductility, which is necessary to withstand dynamic loads.

Bend Test

- First of all you have to bend the bar (typically 180°) using a machine.

- Then check for surface cracks or fractures.

- It may confirms flexibility and resistance to breakage under stress of steel bars.

Ultrasonic Testing (UT)

- non-destructive technique that uses sound waves to find internal defects.

- makes sure there are no unseen voids or cracks in the steel bar.

Fatigue Test

- Simulates repetitive loading and unloading cycles.

- Tests the bar’s ability to withstand stress over extended periods.

Corrosion Resistance Test

- Expose the bar to saline or acidic conditions.

- Observe corrosion levels over time.

- Crucial for construction in coastal or industrial environments.

Impact Test

- Must performed an impact test using a Charpy or Izod impact tester to insure safety measure.

- You have to measures energy absorbed when the bar is struck.

- The you ca determines toughness, especially useful for earthquake-prone areas.

Steel Bars Follow These Standards:

Test results should always be compared to pertinent industry standards, such as:

- The Indian Standard for High Strength Deformed Steel Bars is IS 1786.

- American Standards for Reinforcing Steel (ASTM A615/A706)

- The British Standard for Reinforcement Steel is BS 4449.

Final Thoughts:

- Any excellence and safety dedicated construction worker must know how to inspect the quality of steel bars.

- The steel you use is guaranteed to meet strict quality standards and be appropriate for the requirements of your project.

- A combination of visual inspections, mechanical testing, and chemical analysis are strict quality standards which are not compromised while purchasing steel bars.

- A long-lasting and safe structure depends on the selection of appropriate steel. Which may lead to results like you will face less issues later on.

FAQ’s:

How do you test the quality of steel?

As we discussed above the tensile testing technique to determining the force needed to separate a material. Steel’s strength and ductility are assessed using this test. The force needed to break a steel sample is measured after it is subjected to an increasing load until it breaks.

How to check steel quality at home?

A high-quality TMT steel bar, like ARS, will flex without cracking if you attempt to bend it by hand. As a test of the steel’s qualities, this will demonstrate its strength and flexibility.

What is the physical test for steel bars?

The most popular test for steel bars is the tensile test. It gauges the bar’s elongation, yield strength, and tensile strength. Steel bars must normally have a tensile strength of at least 415 MPa in India. Generally speaking, steel bars must have a minimum strength of 415 MPa.

How to identify steel bar?

When selecting bars, make sure they are marked with the ISI certification. This certification guarantees that the bars fulfil the necessary safety requirements and have passed rigorous quality tests. Without it, the integrity of your construction is at serious risk.

Note: Look for TMT bars bearing the IS:1786 mark at all times.

What are the 4 classes of steel?

The four primary classes of steel are as follows:

- carbon steel.

- stainless steel.

- steel alloy.

- steel tool.