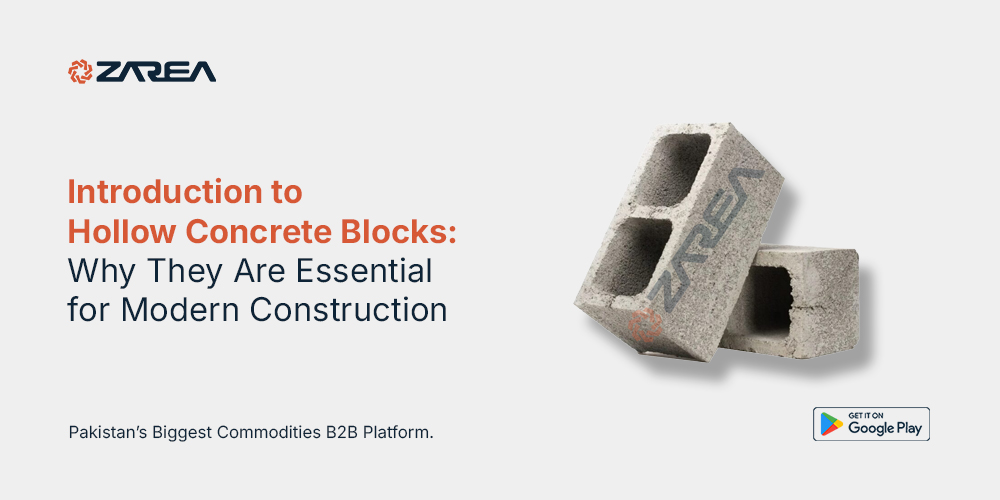

Introduction – Hollow concrete blocks:

Hollow concrete blocks, frequently overlooked in modern construction, form a foundation of efficiency and sustainability in building methods. Let’s explore why these materials are more than just building blocks; they are the essential basis for groundbreaking architectural achievements.

Hollow Concrete Block: The Ultimate Guide to Strength in Construction

Grasping the primary benefits of hollow concrete blocks explains their popularity in different construction situations. Recognized for their strength and adaptability, these blocks play an essential role in building sturdy and long-lasting structures. Their distinctive design, featuring hollow centers, decreases the weight of the block while maintaining its strength. This ingenious engineering achievement guarantees that structures can endure significant external forces, ranging from strong winds to seismic events, rendering hollow concrete blocks a dependable option for safety-oriented developments.

Concrete Hollow Blocks: Their Uses, Properties, Lifespan, and Advantages

Characteristics and Duration of Life

Hollow concrete blocks are praised for their insulating qualities in terms of temperature and sound. Their empty cores, which can be packed with substances like insulation, enhance a building’s energy efficiency. This feature is especially crucial in areas facing severe weather, as it aids in creating a pleasant indoor atmosphere while lowering heating and cooling expenses.

The strength of these concrete blocks is an additional praiseworthy characteristic. These blocks are engineered to endure for decades with minimal deterioration, owing to their strong compressive strength and durability against weather effects. The durability of hollow blocks makes them a cost-effective option over time, as they need less upkeep and replacement than conventional materials such as wood.

Applications in Building

Hollow concrete blocks are highly versatile and are used in numerous areas of construction. They are frequently utilized in:

- Walls that support weight, needing durability while also allowing design flexibility.

- Partition walls designed for lightweight construction while maintaining durability.

- Outer walls that gain from enhanced insulation features.

- Bases that need strong material able to withstand moisture from the ground.

This flexibility renders these concrete blocks essential for residential and commercial construction endeavours.

The Uses of Hollow Concrete Blocks in Construction

In addition to their usual uses in walls and foundations, hollow concrete blocks are also essential for paving and landscaping. Their interconnected structures are perfect for constructing stable and visually appealing garden paths, retaining walls, and driveways. These blocks can be designed to interconnect flawlessly, which not only increases the aesthetic charm of a project but also improves its structural strength.

In extensive construction projects, hollow blocks act as effective options for building fireproof walls and enhancing the thermal insulation of substantial structures. This feature is crucial for complying with contemporary building regulations and sustainability requirements, which increasingly necessitate energy-efficient resources.

What Are the Advantages of Hollow Concrete Blocks?

A key benefit of Zarea’s hollow concrete blocks is the efficiency they provide in construction projects. Their bigger dimensions cover a larger area with fewer units, significantly accelerating the construction process. Moreover, their lightweight characteristics minimize the total structural load, potentially resulting in more creative architectural designs and decreased transportation expenses.

Zarea guarantees that their hollow concrete blocks are produced with accuracy, providing multiple grades appropriate for diverse structural requirements. Grade A blocks are optimal for load-bearing uses because of their greater density and compressive strength, whereas Grade B and C blocks can be used for both load-bearing and non-load-bearing purposes based on the project’s specific needs.

To find out more about the different kinds of hollow concrete blocks and their uses, you can explore the comprehensive descriptions and buying choices offered on Zarea.

Conclusion

- Hollow blocks are not merely construction materials; they are essential components that provide strength, efficiency, and sustainability.

- Their extensive use in contemporary construction highlights their significance and establishes them as a favored option for builders and architects seeking to merge innovation with dependability.

- Welcoming concrete blocks is welcoming the future of building—a future that guarantees durability and reliability against changing architectural needs and environmental issues.

FAQs

How strong are hollow concrete blocks?

These blocks generally provide decent compressive strength ranging from approximately 3 to more than 15 N/mm2, depending on the block’s grade. They are engineered to support substantial weights, rendering them ideal for numerous structural uses in construction.

What is a hollow concrete block used for?

These concrete blocks are widely utilized in the construction sector for building structural walls, retaining walls, and partitions. The empty interiors can also be filled with insulation, improving their effectiveness in energy-efficient architectural designs.

How do you make strong concrete hollow blocks?

Durable concrete hollow blocks are produced by maintaining a balanced mixture of premium cement, fine aggregates, and water. Incorporating additives such as fly ash or silica fume can enhance the strength and durability of the block. Correct curing methods are essential for attaining maximum strength.

How do you reinforce hollow blocks?

Hollow blocks may be strengthened by filling their cavities with concrete and incorporating steel rods. This approach enhances the block structure and also increases its ability to withstand seismic activity, rendering it more resilient to natural forces.

How do you increase the strength of concrete blocks?

Enhancing the strength of concrete blocks can be accomplished by fine-tuning the cement-to-aggregate ratio, utilizing premium cement, and adding reinforcing materials such as slag or fly ash. Sufficient curing duration and techniques are essential for achieving optimal strength.

References

Cement Concrete & Aggregates Australia – Offers comprehensive guides and technical resources on concrete block manufacturing and properties. CCA Australia

National Concrete Masonry Association – Provides detailed technical data and educational materials on various aspects of concrete masonry. NCMA

American Concrete Institute – Contains extensive resources on concrete block standards, guidelines for reinforcement, and best practices in masonry construction. ACI

The Constructor – Civil Engineering Home – Offers detailed articles on the types of concrete blocks, their strengths, uses, and how to enhance their properties. The Constructor

ScienceDirect – Features research articles and papers on the latest advancements in concrete block technology and its structural implications. Science Direct