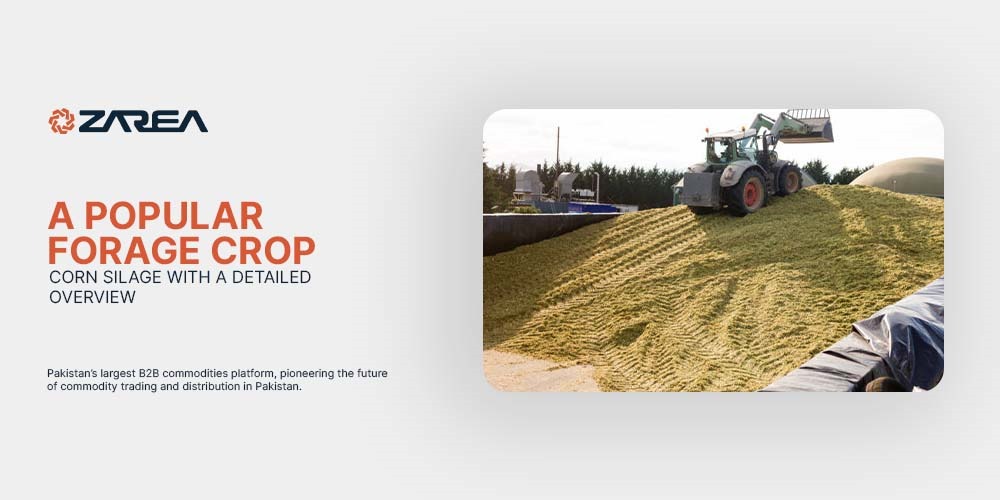

Introduction – Corn Silage:

Corn Silage is a type of fermented feed produced by storing high moisture crops in anaerobic conditions within a structure known as a silo. In summary, Silage is a moisture-rich feed that farmers utilize to nourish their livestock, particularly in the dry season. Composed of grass, corn, maize, and more, silages are created by cutting the crops into tiny pieces and subsequently storing them.

Silage is among the most commonly utilized forage crops in animal husbandry because of its excellent nutritional content and digestibility. It acts as a nutrient-dense feed option for dairy and beef cattle, promoting milk output and weight increase. The method of ensiling corn guarantees its preservation for extended storage while retaining its nutritional value. This article offers an extensive summary of corn silage, covering its production, advantages, nutritional content, and optimal methods for storage and feeding.

The silage is subsequently fermented to create feed for animals. The silage fermentation process occurs in several stages and requires about 3 weeks to finish. The fermentation process is carried out to enhance dry matter consumption and produce a more easily digestible feed.

Want to Buy Corn Silage? Click Here

What is Corn Silage?

Corn silage is a moist, fermented feed made from the whole corn plant, encompassing stalks, leaves, and cobs. It is collected at the ideal level of ripeness and kept in oxygen-free conditions to promote fermentation. This method improves its digestibility and longevity, making it a great feed choice for ruminant animals.

How Silage is prepared?

In the silage production process, the pasture is harvested when the grasses exhibit their peak nutrient content. This stage is reached right before they achieve full maturity. The reason for cutting it just prior to full maturity is that all types of preserved grass, like hay and silage, contain fewer nutrients than fresh pasture, so every effort must be made to ensure the final product is as nutritious as possible.

In the process of Silage making, grass is left to wilt in the field for several hours to lower the moisture content to approximately 60-75%, which is the ideal level. If the grass is left out for an extended period, it could become overly dry or be exposed to rain – and both scenarios will diminish the fermentation’s effectiveness.

Nutritional Composition of Corn Silage:

Corn silage is recognized for its well-rounded nutrient composition, offering:

- Carbohydrates: Abundant in fermentable energy because of elevated starch levels.

- Fiber: Includes beneficial fiber that supports rumen well-being.

- Protein: Usually falls between 7-9% crude protein, varying with the type and stage of harvest.

- Minerals & Vitamins: Comprises vital minerals like calcium, phosphorus, and potassium, as well as vitamins A and E.

- Moisture Level: For the best fermentation, corn silage should ideally contain 60-70% moisture.

Benefits of Corn Silage:

- Elevated Energy Levels: Facilitates quick weight increase in beef cattle and enhanced milk production in dairy cows.

- Affordable Feed: Offers a budget-friendly option compared to grain-centric diets.

- Effective Land Use: Optimizes forage production per acre in comparison to alternative forage crops.

- Extended Storage: Fermentation safeguards the feed, minimizing deterioration and waste.

- Taste: Cattle favor corn silage because of its sweet flavor and soft consistency.

Corn Silage Production Process:

Choosing Corn

- Select hybrid types developed for silage production, featuring high starch levels and good digestibility.

Best Time for Harvesting

- Harvest the corn plant when it attains 32-38% dry matter content (or at the ½ to ¾ milk line stage) to guarantee optimal nutrient preservation.

Cutting and Preparing

- The corn plant is cut into small segments (½ to ¾ inch) to encourage adequate packing and fermentation.

Silage Preparation and Fermentation

- Throughout the fermentation process, the cut grass is chopped into smaller pieces (0.5 inches or 1.3 cms) and then compressed to expel the oxygen more effectively.

- The diced corn is grouped closely in silos, bunkers, or bags to remove oxygen.

- Fermentation starts within 24-48 hours, as lactic acid bacteria decompose sugars to generate lactic acid, which helps preserve the silage.

- Complete fermentation usually requires 3-6 weeks.

Storage Methods for Corn Silage:

To seal the compressed grass with plastic to prevent oxygen entry, large mounds of silage are covered with massive polythene (plastic) sheets and held down (typically with old tires) to achieve optimal compression. Bales, in contrast, are merely wrapped in plastic. When silage is stored in a large pit, tractors and other equipment are typically driven over the grass pile until it becomes compact. When silage is kept in bales, baling machines will compress the grass.

Appropriate storage is crucial for preserving the quality of silage. Typical storage techniques consist of:

- Bunker Silos: Substantial ground-level storage that is covered with plastic to establish anaerobic conditions.

- Trench Silos: Excavated in the soil and coated with plastic for air-tight closure.

- Upright Silos: Vertical structures that reduce space consumption and enhance compaction.

- Silage Bags: Versatile and movable storage solutions for smaller agricultural operations.

Preserving Technique:

Once the fermentation process is complete and all the oxygen has been consumed, lactic acid bacteria begin to proliferate. These are the bacteria required for producing the silage. They are crucial in converting plant sugars into lactic acid, resulting in a decrease in pH (the mixture becomes more acidic). When the pH reaches approximately 4-5, the sugars cease to degrade, and the grass remains preserved until the silage is opened and exposed to oxygen.

Feeding Strategies:

To optimize the advantages of corn silage, take into account these feeding suggestions:

- Gradual Introduction: Slowly include corn silage to avoid digestive issues.

- Balanced Rationing: Mix with high-protein feeds such as soybean meal to fulfill nutritional needs.

- Effective Storage Oversight: Frequently inspect silage for decay and eliminate any moldy sections prior to feeding.

- Tracking Livestock Performance: Watch weight increase and milk output to modify feeding rates as needed.

Challenges and Considerations:

- Moisture Control: Collecting crops at inappropriate moisture levels may result in inadequate fermentation or decay.

- Mycotoxin Contamination: Mold development in inadequately preserved silage can result in mycotoxin generation, which is detrimental to livestock health.

- Nutrient Variation: The nutrient makeup of corn silage differs according to soil health, hybrid variety, and environmental factors.

Advantages of Silage Making:

- Silage retains nearly 85 percent of the nutritional value of the crops.

- Silage can guarantee the availability of high-quality forage in the scarce months and during dry spells. When there is an abundance of green production, it can be stored for later use as silage.

- Holds a greater dry weight of feed compared to a cubic foot of long hay piled in the stack.

Final Thoughts:

Corn silage is an important forage crop that has a major impact on livestock feeding. Its great energy content, affordability, and simple storage options make it a favored option for dairy and cattle farmers. By applying optimal methods in production, storage, and feeding, farmers can enhance the advantages of corn silage, promoting healthier livestock and greater productivity.

FAQ’s:

Which is the best silage in Pakistan?

Saremco International is a top exporter of Corn Silage from Pakistan. We provide some of the highest quality Corn silage in Pakistan.

What are the ingredients in corn silage?

The two most commonly utilized additives in corn silage are limestone and non-protein nitrogen substances. Molasses and grains can be incorporated into corn forage during the ensiling process. Nevertheless, this method mainly serves to enhance the resulting corn silage as animal feed rather than to elevate the quality of the corn forage itself.

Why do cows eat corn silage?

Corn silage is the main feed combined in a mix of haylage, corn meal, soymeal, and other feeds based on the diet. Silage provides the forage in addition to processed corn. Cows require the corn to be processed for proper digestion in the rumen. It’s all about transforming that corn into energy so the cow can generate more milk.

How many kg of silage per acre?

Kg of feed needed: 1 cow x (50% of 40 kg) x 90 days = 1,800 kg of feed; Total after losses: Typically, there are around 15% losses from spoilage, etc. Thus, you will require an additional 15% silage, resulting in 115% x 1,800 kg = 2,070 kg of fresh silage per cow for 90 days.