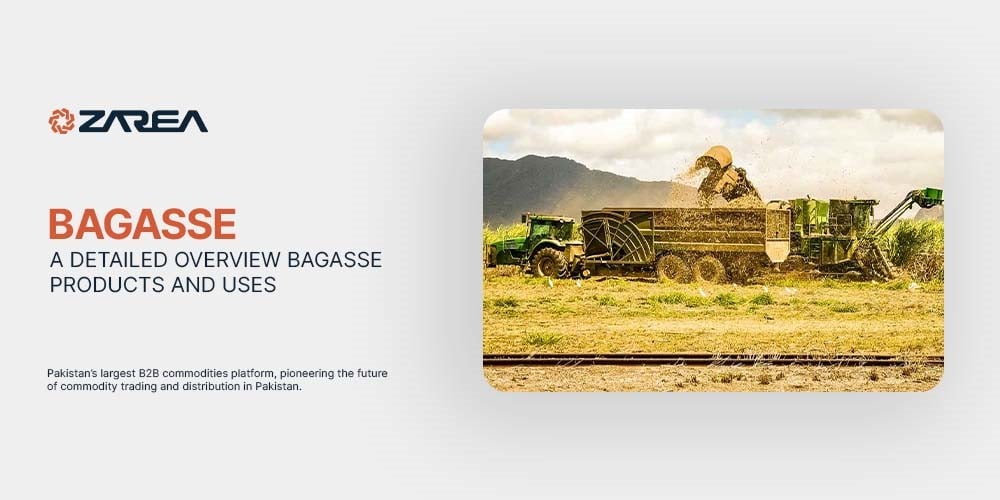

Introduction – Bagasse (A Biomass Product):

What is bagasse used for?

Bagasse is the dry, fibrous pulp left over after crushing sugarcane or sorghum stalks to obtain their juice. It serves as a biofuel for generating heat, power, and electricity, as well as in producing pulp and construction materials.

As the globe transitions to sustainable and environmentally friendly options, sugarcane fiber has received considerable attention for being a versatile and biodegradable byproduct of sugarcane processing. Earlier, people frequently ignored this fibrous substance. But now, different industries are continuously using it in paper making, eco-friendly packaging, biofuel, and also in building materials. In this detailed guide, we will examine what sugarcane fiber is, its advantages, products derived from it, and its increasing importance in sustainable sectors.

What is Bagasse?

Bagasse is the fibrous remainder that remains after the sugarcane stalks are pressed to retrieve their juice. People are reusing it rather than throws away. This renewable biomass is transforming into numerous uses. Sugarcane fibrous waste has transformed into a vital raw material across various sectors these days.

Until recently, sugarcane fiber commonly discarded or decayed. However, today it serves as a renewable resource for making paper goods and as fuel for factories.

Composition of Bagasse

- Cellulose (45–55%) – Offers robustness and longevity

- Hemicellulose (20–25%) – Aids in the flexibility of fibers.

- Lignin (18–24%) – Contributes to structural strength and enhances resistance to decay.

- Ash (1–4%)

- Waxes (<1%)

Key Benefits of Bagasse:

- Environmentally Friendly – entirely biodegradable and compostable, minimizing plastic waste

- Renewable Resource – A byproduct of sugar manufacturing that guarantees sustainability.

- Long-lasting & Heat-Proof – Capable of enduring heat and humidity, ideal for food packaging

- Decreases Carbon Footprint – Aids in reducing greenhouse gas emissions in relation to synthetic materials.

- Economical – Provides a practical substitute for conventional wood-based paper and plastic packaging.

Uses and Products Made from Bagasse:

Many research initiatives have investigated the use of bagasse in creating bio-based materials and as a biofuel for renewable energy generation.

1. Biochar

Sugarcane bagasse (SB) from biomass converts into energy, materials, and chemicals.

2. Fuel

Sugar mills frequently utilize bagasse as a main source of fuel. When combusted in large amounts, sugarcane fiber generates sufficient heat energy to completely fuel a standard sugar mill, with extra energy available. In a typical arrangement, the producer sells this surplus energy to the consumer power grid. Historically, bagasse served as fuel for steam locomotives transporting the harvested cane to the mills.

- Biomass Fuel – In sugar mills, sugarcane fiber is combusted to produce electricity and steam.

- Ethanol Production – Transformed into bioethanol, a substitute for fossil fuels.

3. Animal Feed and Agriculture

Bagasse generated from sugarcane processing provides an appealing raw material for biofuel production and value-added items since it does not compromise food security. Experts view the biochemical production of second generation biohydrogen, biomethane, biomethanol, or bioethanol as an environmentally friendly and economically viable choice. Thermochemical methods like hydrothermal liquefaction, pyrolysis, and gasification of sugarcane fiber offer a promising approach to generate advanced 2G biofuels (such as jet fuel and diesel) and chemicals (for applications in plastics) with minimal life cycle effects.

- Livestock Feed – Converted into feed for cows and various other farm animals

- Soil Enrichment – Utilized as an organic compost substance to enhance soil fertility.

4. Bagasse Pulp, paper, board and packaging

Experts consider the biochemical production of second generation biohydrogen, biomethane, biomethanol, or bioethanol as an environmentally friendly and economically viable choice. This replacement creates pulp with physical characteristics that are ideal for printing and notebook paper, tissue goods, boxes, and newspapers. Manufacturers can also utilize it to produce boards similar to plywood or particle board, referred to as sugarcane fiber boards and Xanita boards. They commonly use these in the manufacturing of partitions and furniture.

sugarcane fiber has emerged as a favored option for packaging tableware. The material is appropriate for both cold and hot uses (up to approximately 120 °C). Moreover, you can safely place it in the freezer and microwave it without issues. It also has fairly good resistance to water and grease, which you can improve through chemical modification.

- Paper Creation – Utilized as a substitute for wood pulp in producing environmentally friendly paper.

- Disposable Tableware – Plates, bowls, cups, and utensils crafted from sugarcane fibers are both biodegradable and compostable.

- Food Packaging – Containers, trays, and boxes utilized by restaurants and fast-food establishments for takeout.

5. Construction Materials

- Particle Boards – Utilized as a substitute for plywood and MDF in furniture and construction projects.

- Thermal Insulation Panels – Offers sound and heat insulation in environmentally friendly structures.

Bagasse – Plant Fibre Products for Human Consumption:

When bagasse contrasts with plastic or polystyrene items, these capable products have composted both industrial and at home. Under composting conditions, sugarcane fiber and its contained food waste will decompose into nutrient-dense compost suitable for use as fertiliser and soil enhancer.

A type of treated sugarcane fiber is sugarcane bagasse. It has occasionally included in human food. It is a soluble fiber that may aid in promoting intestinal regularity. A study involving animals indicates that sugarcane fiber along with a high-fat diet might aid in managing type 2 diabetes. It serves as an excellent source of cerotic and lignoceric acids.

Challenges and Future Potential:

Although bagasse offers numerous advantages, factors like elevated production expenses and insufficient awareness continue to obstruct its broad acceptance. However, sugarcane fibers have been used for expected to grow significantly in the coming years. It’s because of advancements in technology and an increasing worldwide emphasis on sustainability sectors.

Conclusion:

Bagasse has evolved beyond merely being a byproduct of sugar manufacturing; it has turned into a significant resource for sustainable packaging, renewable energy, and environmentally friendly building materials. As industries and consumers move toward eco-friendly options, sugarcane fiber is poised to significantly influence the creation of a more sustainable future with Zarea.

Would you like additional information on sugarcane fiber production methods or market developments? Share your thoughts in the comments!

FAQ’s:

Is bagasse a fuel?

Bagasse is a sustainable fuel that’s why it is utilized to obtain carbon credits. These features of bagasse-derived cogeneration offer a remedy for global warming. Mauritius possesses few renewable energy resources and lacks any discovered oil, gas, or coal reserves.

Is bagasse a waste product?

Bagasse – A pulp extracted from sugar cane. It’s a by-product thats generates during the production of sugar cane. Mainly a fibrous material that’s left behind after the juice has been extracted from the sugarcane stalks.

What are the disadvantages of bagasse?

What are the drawbacks of using bagasse as a food packaging material? Despite having a great resistance to both high and low temperatures, bagasse can lose some of its durability when it contains foods exceeding 95 degrees Celsius. Alternatively, bagasse is impeccable as a food packaging material.

Is bagasse eco-friendly?

Bagasse is a natural, safe, and highly renewable material created from a waste plant fiber byproduct resulting from the processing of sugarcane, sorghum, or agave. This renders it among the most environmentally friendly materials available on Earth.

Can bagasse be recycled?

Manufacturers make bagasse from extracted sugarcane pulp. A paper and cardboard recycling facility also processes this pulp. They do not heavily contaminate it with food remnants. Workers create sugarcane pulp items under high pressure and temperatures, transforming sugarcane pulp into a moulded shape.