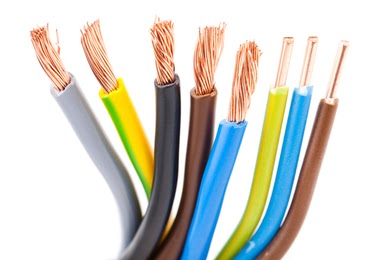

Details of Wire & Cable by an expert. There are many types of cables available in the market, each with a specific set of applications. Finding the cables according to your specific needs is not easy. Understanding some issues that should affect your buying decision can help you find the right cable for your needs.

Important points to consider include:

Use of Cable

Nature of Cable

Temperature

Flexibility of Cable

Levels of Cable

Budget

Knowing the details of your application that you need can help you to communicate with a cable and connection specialist.

The information you need:

When you call or email a cable and wiring expert to get the best product for your project. Before driving or shopping, combine any needs you have with the following areas:

Rope Use

Cables have connectors ranging from one to 100 depending on their purpose. If you know how the cable will be used in the future, your service provider can better determine which combinations should be included, and which items to use.

Nature

The metal structure of the cable should be able to compete with the environment, otherwise it will provide its long-term performance. For example, if you expect the cable to have a large number of external uses, your service provider may recommend a tin can, which can compete with corrosion and oxidation.

If your new cable is to be used in tropical areas, copper-plated copper is better. Having this information makes sure you get the cable according to your need.

In addition to the choice of metal, different cables have different layers of external protection. A steel tube that protects ropes or metal bands called Jacketing which is used to protect the cables.

For weatherproof cords, carbon blanks can be combined with PVC, hard PVC, or PE jacketing. If the area has a lot of bad weather, the jacketing can be polypropylene, poly tetra fluoro ethylene, or polyurethane layers instead.

Temperature

Ventilators provide cables with strength to compete extreme temperatures in indoor and outdoor applications. With suitable materials, manufacturers can install cables to keep them safe for use in such kinds of areas that have low temperatures such as 65 ° C or up to 250 ° C. All cables, no matter how they work, must be closed under atmospheric conditions.

Flexibility

Cables that are distributed throughout the day require great flexibility so that they do not wear. You can request to install a cable in these three different degrees of flexibility: standard, flexible, and flexible robot. The wiring itself plays a role in flexibility by means of tight, strong wires with low gauges or very thin wires.

Various jackets can disrupt or allow for complete flexibility. Polyurethane is an excellent choice of jacket because it gives strength and flexibility. If the cable have to be tightened completely instead, manufacturers can make them from solid conductors.

Levels

Every cable must also meet operating standards and safety standards. Other standards to consider include:

ISO 9001 (International Organization for Standardization)

RoHS (Hazard Prevention)

CE Mark

NEC (National Electricity Code)

UL (Underwriters Laboratories)

CSA (Compliance, Security, Accountability)

OSHA (Occupational Safety and Health Management)

VDE Association for Electrical, Electronic and Information Technologies

LF (Lead Free)

Mil-Spec (Military Specifications and Standards)

Details / Drawings

Details of Wire & Cable by an expert. Manufacturers may meet certain requirements if they are provided with detailed drawings. If you need to redesign an existing cable or a redesigned cable to meet critical standards, your rope and cabbage company can inform you of their skills and whether they can do the job before the project begins. They need as much detail as possible to make that determination. They can also deal with previous shortages in older cables.

Budget

Knowing your budget before placing an order or consulting a cable manufacturer can help them find the right materials and procedures. They can ensure that you get the best performance within your budget.